AD100 Mini Variable Speed Drive

| Items | Specification | |

| Control mode | Control mode | V/F control |

| Starting torque | 0.5Hz 150% | |

| Speed adjust range | 1:100 | |

| Motor type | General induction motor | |

| Function design | Highest frequency | General vector control :400Hz |

| Frequency resolution | Digital setting: 0.01Hz analog setting:maximum×0.025% | |

| Carrier frequency | 0.5K~16KHz, the carrier frequency can be adjusted by temperature automatically | |

| Frequency reference setting method | Digital of Control panel, analog AI1, AI2, potentiometer of control panel, UP/DN control, communication, PLC pulse frequency | |

| Acceleration./deceleration characteristic | Linear curve and S curve accel. /decel. mode, range of time: 0.0 to 65000S. | |

| V/F curve | 3 mode: linear, multiple points, N Power | |

| V/F separation | 2 times separation: totally separation, half separation | |

| DC braking | DC braking frequency: 0.0 to 300Hz, DC braking current: 0.0% to 100% | |

| Braking unit | Standard built in | |

| Jog function | Job frequency range: 0.0 to 50.0Hz, | |

| Configured PID function | Easy to perform pressure, flow, temperature close loop control. | |

| PLC multiple speed | To achieve 16 segment speed running through built in PLC or terminal control | |

| Common Dc bus | Multiple drives use one DC bus for energy balance. | |

| Auto voltage regulation (AVR) | Enable to keep output voltage constant when grid fluctuation | |

| Over load tolerance capability | G type model: 150% rated current for 60s, 180% rated current for 3s, | |

| Stall protection control when over current, over voltage | Carry out limiting automation for running current, voltage to prevent over current, over voltage frequently | |

| Rapid current limit function | Minimize the IGBT module broken to protect the AC Drive, maximum reduce the over current fault. | |

| Torque limit and torque control | "Excavator" characteristics , torque limit automatically during motor running. Torque control is available in close loop vector control mode. | |

| Friendly interface | Display "Hello" when power on. | |

| Multiple function key JOG button | Forward Jog, reverse Jog, forward/reverse switch | |

| Timing control function | A total running time and total running time calculating | |

| 2 group motor parameters | To achieve two motor switchover freely, control mode is selectable | |

| Motor over heat protection | Accepting motor temperature sensor signal input via AI1 terminals. | |

| Multiple kinds encoder * | Compatible collector PG, differential PG, and rotary transformer Encoder( resolver). | |

| Command source | Control panel, control terminals, series communication, switch freely. | |

| Frequency source | Digital setting, analog current/voltage, pulse setting, serial communication, main and auxiliary combination. | |

| Protection function | Short circuit detect when power on, input/output phase loss, over voltage, over current, under voltage, over heat, over load protection. | |

| Environment | Application site | Indoor, free of exposure to sunlight, no dusty, no corrosive, no inflammable gas, no oil and water vapor, and water dipping |

| Altitude | Lower 1000m | |

| Environment temperature | -10℃~+40℃, power derated for 40~50℃, rated current derated 1% for 1℃ increasing. | |

| humidity | Less than 95%, no water condense. | |

| storage | -40~+70℃ | |

| Protection IP rating | IP20 | |

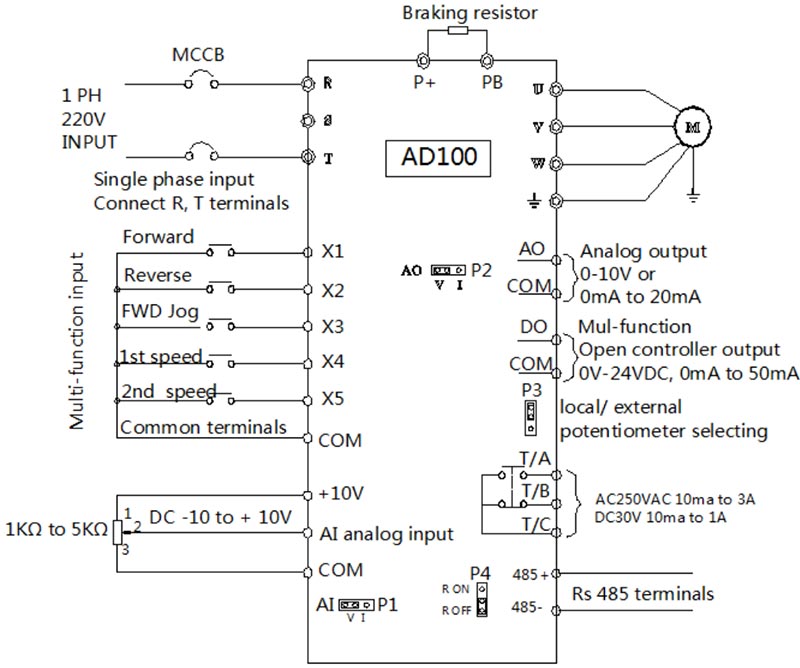

Wiring diagram

It has 5 digital input, DI5 can use for high pulse train input

1 analog signal input, 1 analog output, 1 digital output, and 1 relay output.

In built Rs485 terminal, external remote keypad

Terminals diagram:

AD100 frequency inverter application examples.

1. Food processing machinery

Bakery equipment, confectionary equipment, tea-making machine, noodle-making machines, candy-wrapping machines, rice/barely milling machines, flour milling machines, food mixers, food slicers, fruit sorting machines, etc.

Advantage:

● You can set the operating frequency according to the required work rate.

● Run and Stop keys.

● Ensures safety in the event of an instantaneous power failure.

● Low noise

● High torque from start up to the rated speed.

2. Conveyance machinery

Conveyors, automatic warehousing systems etc. Prevent the collapse of cargo on the conveyor.

3. Fans & pumps

Built in fans- pumps in industrial machines, water supply and sewage systems, driers, etc.

Energy-saving mode

The variable torque and automatic energy saving modes help saving energy by passing optimal current in accordance with the load.

Automatic process control

Allows a motor to keep running and accelerate smoothly upon the recovery of power even in the event of instantaneous power failure.

Enable an uninterrupted operation without causing a trip.

4. Health, medical and nursing care equipment.

Stair lifts, nursing bed, bubble baths, health care equipment, medical equipment

5. Environment and daily-life-related machinery

Commercial ironing boards, car washing machines, Garbage disposers, dust collectors, Dries, etc.

6. Packing machinery.

Inner packaging machine, packing machines, output packing machines, membrane packing machines