*AD350 sensorless vector control inverter can’t performance close loop vector control because there are no PG connector. If you need sensor vector control mode please select PV800’s VFD.

| Items | Specification | |

| Control mode | Control mode | V/F control, sensorless vector control |

| Starting torque | 0.5Hz 150%, 0.2Hz 150% rated torque | |

| Speed adjust range | 1:100 under VF control, 1:500 sensorless vector control | |

| Motor type | General induction motor/ Permanent magnet synchronous motor (PMSM) | |

| Function design | Highest frequency | General vector control :400Hz |

| Frequency resolution | Digital setting: 0.01Hz analog setting:maximum×0.025% | |

| Carrier frequency | 0.5K~16KHz, the carrier frequency can be adjusted by temperature automatically | |

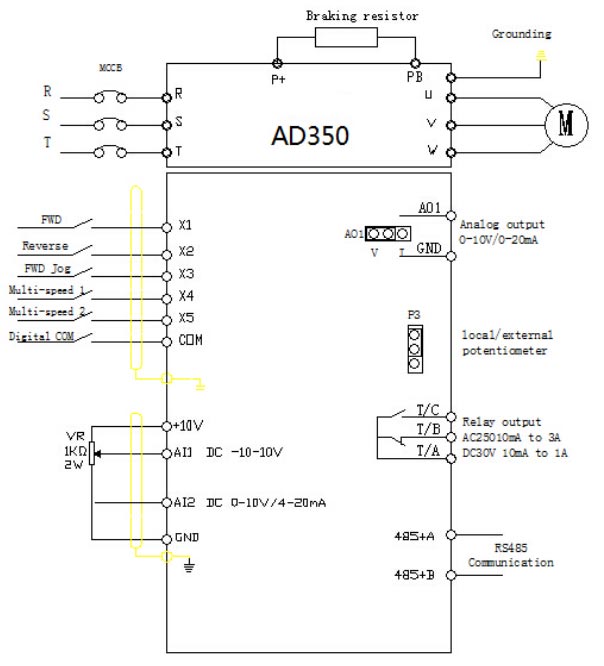

| Frequency reference setting method | Digital of Control panel, analog AI1, AI2, potentiometer of control panel, UP/DN control, communication, PLC pulse frequency | |

| Acceleration./deceleration characteristic | Linear curve and S curve accel. /decel. mode, range of time: 0.0 to 65000S. | |

| V/F curve | 3 mode: linear, multiple points, N Power | |

| V/F separation | 2 times separation: totally separation, half separation | |

| DC braking | DC braking frequency: 0.0 to 300Hz, DC braking current: 0.0% to 100% | |

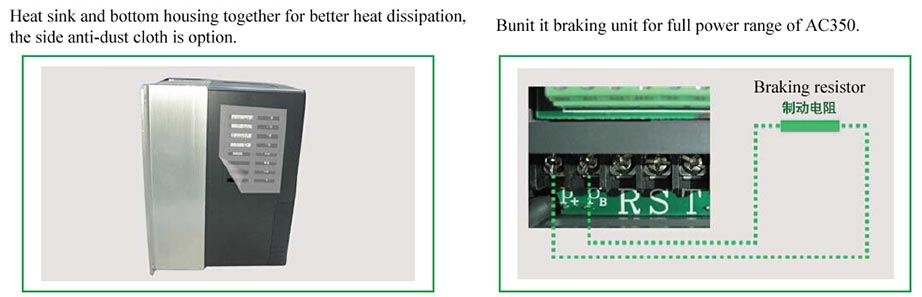

| Braking unit | Standard built in | |

| Jog function | Job frequency range: 0.0 to 50.0Hz, | |

| Configured PID function | Easy to perform pressure, flow, temperature close loop control. | |

| PLC multiple speed | To achieve 16 segment speed running through built in PLC or terminal control | |

| Common Dc bus | Multiple drives use one DC bus for energy balance. | |

| Auto voltage regulation (AVR) | Enable to keep output voltage constant when grid fluctuation | |

| Over load tolerance capability | G type model: 150% rated current for 60s, 180% rated current for 3s, | |

| P type Model: 120% rated current for 60s, 150% rated current for 3s. | ||

| Stall protection control when over current, over voltage | Carry out limiting automation for running current, voltage to prevent over current, over voltage frequently | |

| Rapid current limit function | Minimize the IGBT module broken to protect the AC Drive, maximum reduce the over current fault. | |

| Torque limit and torque control | "Excavator" characteristics , torque limit automatically during motor running. Torque control is available in close loop vector control mode. | |

| Features | Friendly interface | Display "Hello" when power on. |

| Multiple function key JOG button | Forward Jog, reverse Jog, forward/reverse switch | |

| Timing control function | A total running time and total running time calculating | |

| 2 group motor parameters | To achieve two motor switchover freely, control mode is selectable | |

| Motor over heat protection | Accepting motor temperature sensor signal input via AI1 terminals. | |

| Multiple kinds encoder * | Compatible collector PG, differential PG, and rotary transformer Encoder( resolver). | |

| Command source | Control panel, control terminals, series communication, switch freely. | |

| Frequency source | Digital setting, analog current/voltage, pulse setting, serial communication, main and auxiliary combination. | |

| Protection function | Short circuit detect when power on, input/output phase loss, over voltage, over current, under voltage, over heat, over load protection. | |

| Environment | Application site | Indoor, free of exposure to sunlight, no dusty, no corrosive, no inflammable gas, no oil and water vapor, and water dipping |

| Altitude | Lower 1000m | |

| environment temperature | -10℃~+40℃, power derated for 40~50℃, rated current derated 1% for 1℃ increasing. | |

| humidity | Less than 95%, no water condense. | |

| storage | -40~+70℃ | |

| Ip rating | IP20 | |

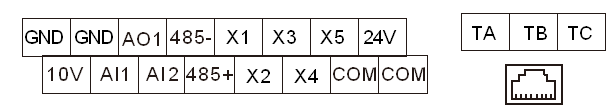

* 5 multiple digital input terminals ( 5DI) input.

* 2 analog terminals input, 1 analog terminals output

* local relay 1 output.

* 1 Rs485 port.

1. Food processing machinery

Bakery equipment, confectionary equipment, tea-making machine, noodle-making machines, candy-wrapping machines, rice/barely milling machines, flour milling machines, food mixers, food slicers, fruit sorting machines, etc.

2. Conveyance machinery

Conveyors, automatic warehousing systems etc. Prevent the collapse of cargo on the conveyor.

3. Fans & pumps

Built in fans- pumps in industrial machines, water supply and sewage systems, driers, etc.

Energy-saving mode

The variable torque and automatic energy saving modes help saving energy by passing optimal current in accordance with the load.

Automatic process control

Allows a motor to keep running and accelerate smoothly upon the recovery of power even in the event of instantaneous power failure.

Enable an uninterrupted operation without causing a trip.

4. Health, medical and nursing care equipment.

Stair lifts, nursing bed, bubble baths, health care equipment, medical equipment

5. Environment and daily-life-related machinery

Commercial ironing boards, car washing machines, Garbage disposers, dust collectors, Dries, etc.

6. Packing machinery.

Inner packaging machine, packing machines, output packing machines, membrane packing machines