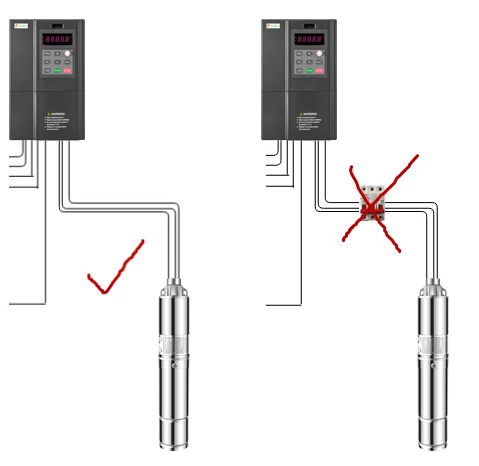

Proper electrical connections are essential when installing a solar pump system or any installation involving an inverter and a pump motor. A common question is: Is it safe to place a circuit breaker between the AC output of the inverter and the pump motor? The short answer is no. Doing so can cause a series of problems that may damage the inverter and the pump motor.

Why connecting a circuit breaker can be dangerous

● Electrical compatibility issues:

The AC output of the inverter has specific electrical parameters, such as frequency, phase, and amplitude, which match the operating characteristics of the pump motor. Adding a circuit breaker between the inverter and the pump motor may interfere with these electrical parameters, resulting in system performance degradation or instability.

● Overlapping protection mechanisms:

Solar pump systems are usually already equipped with comprehensive protection mechanisms, such as overcurrent, overvoltage, and undervoltage protection functions inside the inverter. Connecting a circuit breaker to the AC output of the inverter may cause overlapping protection mechanisms, increasing the complexity of the system and potential failure points.

● Risk of circuit breaker misoperation:

The circuit breaker will trigger a protective action and cut off the circuit under certain conditions. However, if the circuit breaker cuts off the connection between the inverter and the pump motor due to misoperation, it may cause the pump motor to stop suddenly, affecting the normal operation of the system and the continuity of water supply.

● Safety hazards:

Improper installation or use of circuit breakers may pose safety hazards. For example, if the circuit breaker fails to cut off the circuit in time under fault conditions, it may cause serious consequences such as equipment damage or fire. In addition, the selection and rating of the circuit breaker also need to match the electrical parameters of the system, otherwise it may cause electrical failures.

4 safe alternatives for connecting the inverter to the pump motor

While it is unsafe to connect a circuit breaker directly between the inverter AC output and the pump motor, here are some safe alternatives:

● Use appropriate cables and connectors:

Choose cables and connectors that meet the system electrical parameter requirements to ensure that the electrical connection between the inverter and the pump motor is reliable and stable.

● Install overvoltage and overcurrent protectors:

Install overvoltage and overcurrent protectors at the inverter output or pump motor input to provide additional electrical protection. These protectors can cut off the circuit in time when the system has overvoltage or overcurrent conditions, protecting the safety of equipment and systems.

● Use soft start technology:

Use soft starters or frequency converters to start and control the operation of pump motors. These devices can gradually increase the voltage and current of the motor, reduce shock and vibration during startup, and extend the service life of equipment and systems.

● Regular inspection and maintenance:

Regularly inspect and maintain the solar pump system, including components such as inverters, pump motors, cables, and connectors. Timely discover and deal with potential electrical faults and safety hazards to ensure the normal operation and safety of the system.

In summary, it is unsafe to connect a circuit breaker between the AC output of the solar pump inverter and the pump motor. To ensure the stability and safety of the system, safe alternatives such as using appropriate cables and connectors, installing overvoltage and overcurrent protectors, using soft start technology, and regular inspection and maintenance should be used.