Key product features.

● Adopt the same hardware design and configuration as AD350 and AD800's VFD.

● High performance flux vector control for IM and PMSM

● Excellent quick response with vector control

● High starting torque even under low speed.

● Torque limit for machine safety protection

● Rapid current limit, up to 20 kinds protection function.

● Latest generation Infineon IGBT modules using

Outstanding motor control performance

● Torque respond speed ≤5ms in OLV without PG

● Wide input voltage range, and work above 45℃ is available

● Outstanding overload capacity, 150% rated current for 60s, 180% rated current for 3s, 200% rated current for instantaneous.

● Speed range 1:100 (SFVC), 1:1000 (CLVC)

● Startup torque, G type: 0.5 Hz/150% (SFVC); 0 Hz/180% (CLVC), P type: 0.5 Hz/100%

● Torque control accuracy, ± 5% (CLVC)

Hardware enhanced features.

● 1. Ti 's 32 bit DSP ( 28034/35), Germany Infineon intelligent modules;

● 2. Sealed cabinet, conformal coating on PCB;

● 3. Adopt using aviation plugs that have good quality water proof, gas and oil proof. (options)

● 4. Imported high-speed ventilation fan with 24V DC power supply, good cooling effect;

● 5. Lower failure rate and long service lift

| Items | Specification | |||

| Control mode | Control mode | SVC in open loop | V/F control | Close loop vector control |

| Starting torque | 0.5Hz 180% | 0.5Hz 150% | 0.00Hz 180% | |

| Speed adjust range | 1:100 | 1:100 | 1:1000 | |

| speed stabilizing | ±0.02% | |||

| precision | ||||

| Torque precision | NO | NO | ±5% | |

| Motor type | General induction motor,permanent magnet synchronous motor* | |||

| Functin design | Highest frequency | General vector control :400Hz V/f control:4000Hz | ||

| frequency resolution | Digital setting: 0.01Hz analog setting: maximum×0.025% | |||

| carrier frequency | 0.5K~16KHz, the carrier frequency can be adjust by temperature automatically | |||

| Frequency reference setting method | Digital of Control panel, analog AI1, AI2, potentiometer of control panel, UP/DN control, communication, PLC pulse frequency | |||

| Accel./decel. characteristic | Linear curve and S curve accel. /decel. mode, range of time: 0.0 to 65000S. | |||

| V/F curve | 3 mode: linear, multiple points, N Power | |||

| V/F separation | 2 times separation: totally separation, half separation | |||

| DC braking | DC braking frequency: 0.0 to 300Hz, DC braking current: 0.0% to 100% | |||

| Braking unit | Built in braking unit up to 15kw, optional is 18.5kw to 75kw, external built in for above 93kw. | |||

| Jog function | Job frequency range: 0.0 to 50.0Hz, the accel. and decel. time of Jog | |||

| Configuration PID | Easy to perform pressure, flow, temperature close loop control | |||

| PLC multiple speed | To achieve 16 segment speed running through built in PLC or terminal control | |||

| Common Dc bus * | Multiple inverters use one DC bus for energy balance. | |||

| Auto voltage regulation (AVR) | Enable to keep output voltage constant when grid fluctuation | |||

| Over load tolerance capability | G type model: 150% rated current for 60s, 180% rated current for 2s, | |||

| P type Model: 120% rated current for 60s, 150% rated current for 3s. | ||||

| tall control when over current, over voltage | Carry out limiting automation for running current, voltage to prevent over current, over voltage frequently | |||

| Fast current limit function | minimize the IGBT module broken to protect the inverter, maximum reduce the over current fault. | |||

| Torque limit and torque control | "Excavator" characteristics , torque limit automatically during motor running. Torque control is available in close loop vector control mode. | |||

| features | friendly interface | Display Hello when power on. | ||

| Multiple function key JOG button | It can set for Forward Jog, reverse Jog, forward/reverse switch | |||

| Timing control function | A total running time and total running time calculating | |||

| 2 group motor parameters | To achieve two motor switching freely, control mode is selectable | |||

| Motor over heat protection | Accepting motor temperature sensor signal input via AI1 terminals. | |||

| Multiple kinds encoder * | Compatible collector, difference, and rotary transformer Encoder. | |||

| Command source | Control panel, control terminals, series communication, switch freely. | |||

| Frequency source | Digital setting, analog current/voltage, pulse setting, serial communication, main and auxiliary combination. | |||

| Protection function | Short circuit detect after power on, input/output phase missing, over voltage, over current, under voltage, over heat, over load protection. | |||

| Environment | Application site | Indoor, free of exposure to sunlight, no dusty, no corrosive, no inflammable gas, no oil and water vapor, and water dipping | ||

| Altitude | Lower 1000m | |||

| environment temperature | -10℃~+40℃, power derate for 40~50℃, rated current derated 1% for 1℃increasing. | |||

| humidity | Less than 95%, no water condense. | |||

| storage | -40~+70℃ | |||

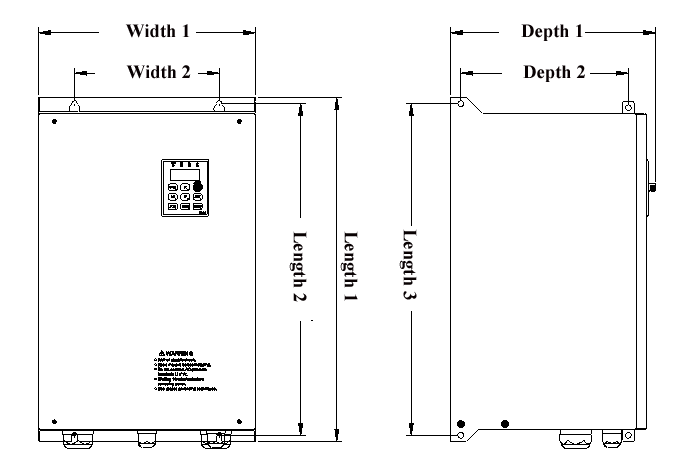

| Models | Power | L1 | W1 | D1 | L2 | W2 | L3 | D2 | SLOT HOLE |

| External size | Install size 1 | Install size 2 | |||||||

| SD800-4T0.7/3.7GB | 0.75-3.7kw,380V | 230 | 130 | 177 | 215 | 90 | 215 | 140 | M5 |

| SD800-4T5.5/7.5GB | 5.5-7.5KW,380V | 320 | 180 | 210 | 305 | 120 | 305 | 170 | M5 |

| SD800-4T11.0/15GB | 11-15kw, 380V | 390 | 230 | 225 | 375 | 160 | 375 | 180 | M6 |

| SD800-18.5/22/30G | 18.5-30kw, 380V | 430 | 230 | 225 | 375 | 160 | 375 | 180 | M6 |

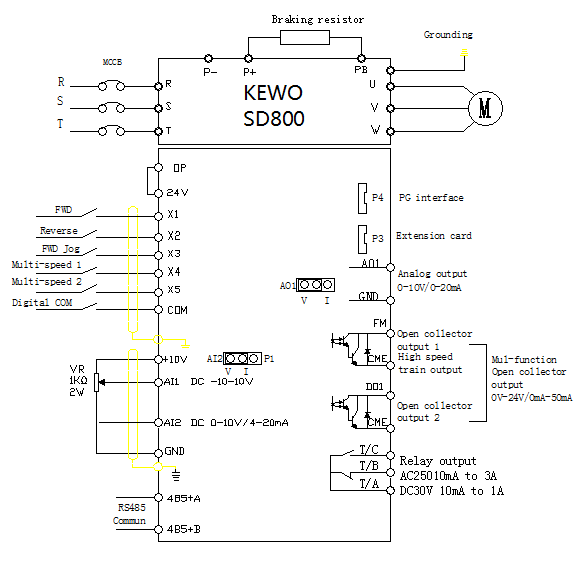

Wiring diagram of SD800. ( the same as AD800 series)

● It has 5 digital I/O input, compatible sink and source way. (PNP an NPN)

● 2 Analog input, support -10V to 10V, 0-10V, 0/4 to 20mA.

● 1 Analog output ( 0-10V/0-20mA is selectable)

● 2 collector output ( FM and CME support the high pulse output).

● 1 relay output.

● Extension PG, I/O card are available.

SD800 Sealed frequency inverter external and installation dimension

Metal processing, CNC tooling machine, cable drawing machine.

Boiler air blower, induced draft fan, exhaust fan

municipal Construction , HVAC

circulating water pump, Fill pump, fuel delivery pump

Paper making equipment, chemical industry, pharmaceutical industry, textile industry